AILSPL is one of the pioneer into the In-Plant Logistics/In-Factory Logistics operations in India. We are also recognized among leading in-plant logistics companies in Pune, offering tailored solutions for diverse industries.

To increase efficiency, controlling internal logistics in factories is just as crucial as controlling production processes. That’s why more businesses are turning to in-plant logistics services in Pune to optimize their manufacturing operations and reduce internal delays.

Our specialised in plant logistics services are in line with the production schedules of our clients. We have a significant impact on our clients' in-plant operations optimisation.

Through the use of technology integrated into our in-plant logistics systems for factories, we provide real-time data of all types needed for planning improvements in efficiency and precision in operations. We offer services like kit creation and building, trolley loading, high-value parts management, material receipt and physical verification, just-in-time (JIT) and just-in-sequence (JIS) operations and more through our Stores and Line Feeding (SLF) process.

Understanding In Plant Logistics

In-plant logistics refers to the management of material handling, storage, and distribution activities within the boundaries of a manufacturing or production facility.

This type of logistics focuses on the movement and flow of raw materials, components, semi-finished products, and finished goods within the plant itself

In-plant logistics is essential for maintaining efficient production operations, ensuring timely supply to production lines, and minimizing delays or bottlenecks in the manufacturing process.

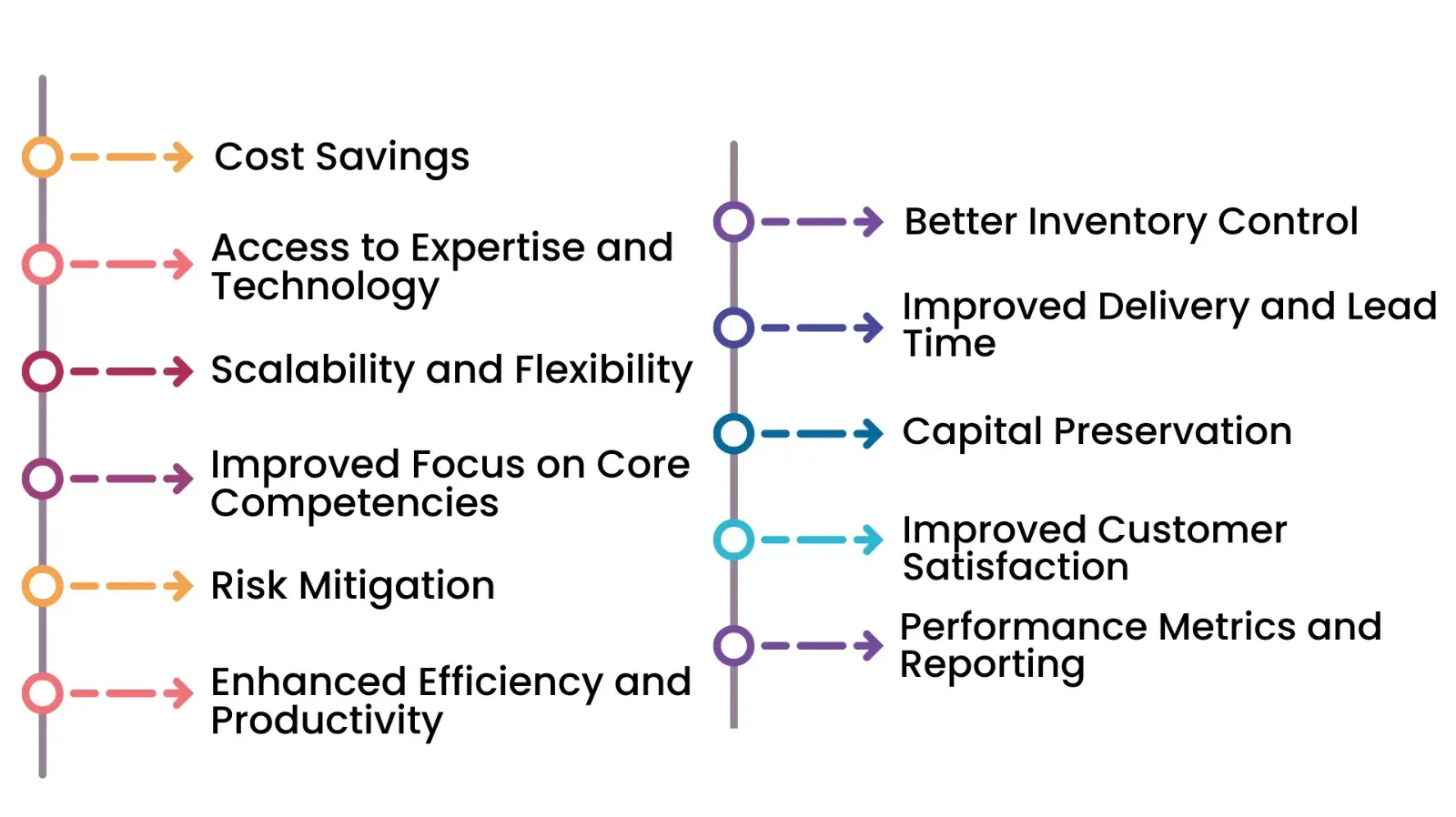

When these operations are outsourced to a third-party logistics provider (3PL), companies can leverage external expertise and resources to improve efficiency, reduce costs, and enhance overall operations.